The principle, use and light source selection of UV (UV) light curing

The principle, use and light source selection of UV (UV) light curing

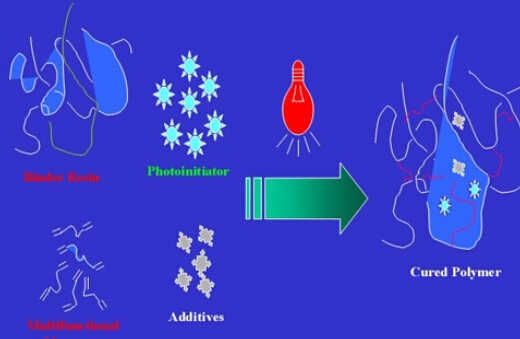

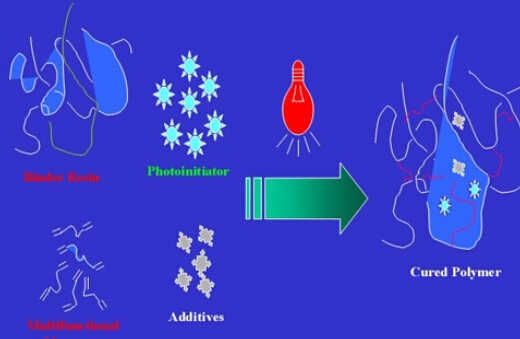

UV Curing Technology (UV) refers to a special formula system (called light curing) adding photoinitiator (or photosensitizer), ultraviolet (UV) absorption after high intensity UV light curing device after generating reactive radicals or cationic polymerization, resulting from grafting and crosslinking reactions so, in a certain period of time by the liquid into a solid technology.

UV curing system (UV system) is mainly composed of optically active monomer (also called reactive diluent, namely simple compounds with unsaturated double bonds is the most commonly used acrylic compounds, mainly to improve the comprehensive performance and improve the curing rate, enhanced rheology effect) optically active oligomer, photoinitiator is composed of three parts. When irradiation of UV curing system, the system will stimulate the decomposition of photoinitiator, formation of reactive free radicals, and the reaction system in double impact growth chain, this reaction continues to make optically active monomers and oligomers of double bonds in the open form of ultraviolet cured polymer crosslinking. The UV system is divided into free radical system and cationic system, and the curing mechanism is different. The free radical system is excited by UV irradiation to produce free radicals, initiating polymerization and cross-linking of monomer and prepolymer. Cationic system is formed by cationic photoinitiator, which is produced by strong proton acid and catalyzed addition polymerization.

Taking the free radical system as an example, the curing of UV free radical needs the following steps:

(1) the free radical photoinitiator is irradiated by UV, and the active free radical is generated by the excitation decomposition.

(2) chain initiating: the free radical produced by the initiator initiating the unsaturated double bonds of the resin or monomer molecules to produce a new free radical;

(3) chain growth: free radicals produced by resins and monomers can continue to initiate free radicals in the resin and monomer molecules and generate free radicals.

(4) chain termination: in chemical reactions, free radicals contain unpaired electrons, which are very active. They are very prone to the radical reaction or acidification, which terminates the chain reaction. Through the above reaction, the polymer is generated and the liquid is converted into solid.

UV curing means under UV photoinitiator, photon absorption of specific wavelengths, excited state, the formation of free radicals and cations, then through intermolecular energy transfer, the polymerizable prepolymer and the photosensitive monomer into the excited state, charge transfer complex, the complex constant the crosslinking polymerization of polymer have solidified into a three-dimensional network structure in a very short period of time.

It is a key part of the UV curing system that absorbs radiation energy and causes the unsaturated double bond crosslinking curing of monomers and oligomers.

UV light curing technology is a new technology of green industry. Once approved by the North American radiation curing Committee, it has the characteristic of "5E", which fully demonstrates the characteristics of the technology. The so-called 5E, Efficient, UV, and curing can be completely cured in a few seconds, the production efficiency is higher; Energy saving, UV products are energy saving, fast curing at room temperature, its energy consumption is generally only heat cured 1/10 ~ 1/5; Environmentalfriendly, environmental friendly, contained no or only a small amount of solvent UV curing materials at the same time, UV curing the energy into electricity, no oil or gas, without CO2, the UV curing is known as the "green technology"; Economy, economy, UV curing device is compact, assembly line production, processing speed, thus saving space, high labor productivity, UV curing technology guarantee more thin film, and has excellent performance and reduce the consumption of raw materials, to reduce the economic cost; Enabling, wide adaptability, the UV product can be adapted to a variety of substrates Such as paper, wood, plastic, metal, leather, stone, glass, ceramics and so on almost all hard materials and soft materials.

The UV light curing system is divided into free radical system and cationic system, and the curing mechanism of different systems is different. Free radicals mainly produce free radicals by light irradiation, which lead to the polymerization and crosslinking reaction of monomers and prepolymers to achieve the effect of curing. Cationic photoinitiators are irradiated by a cationic photoinitiator to produce a strong proton acid, which is added to polymerize to make a curing process. The advantages of UV (UV) curing:

1, excellent performance, wear-resistant, solvent resistant, strike resistance, high strength;

2, the use of a single system is not mixed, making it easy to use;

3. It can solidify instantaneously, save a lot of time, improve production efficiency, and be beneficial to automatic production line.

4, the curing of low temperature requirements, thus saving energy, more able to solve the high temperature curing material, compared to heat curing energy consumption. The degree of curing is also high.

5. Environmental health, no use of solvent, no volatile gas, no pollution to the environment, no harm to the human body

Chengdu gigantic photoelectric fast start iodide gallium lamp is applied to produce strong 320-450nM ultraviolet and near ultraviolet metal halide discharge lamps, specially designed for the photochemical process of strong ultraviolet and near ultraviolet light source. Gigantic photo electric iodine gallium lamp is especially suitable for printing, printing, printing and PS printing. It is also suitable for plate printing and printed circuit board printing. This series lamp has many advantages such as stable spectrum, uniform illumination, long life and short printing time.

Chengdu gigantic UV UV curable lamp has been developing rapidly in recent years by using high intensity ultraviolet lamp and radiation. It has the characteristics of instant curing, saving time and saving electricity, saving space and no pollution.