Many semiconductors that can produce electroluminescence cannot be grown into single crystal form, and their physical properties are not well understood. However, the manufacture of p-n junctions requires the use of high-purity materials to control the incorporation of impurities.

When selecting semiconductors, it is very meaningful to carefully study the factors that affect electroluminescence.

Crystal Growth The effect of the p-n junction requires a single material; and the material should have the least defects, and the doping control rate should be less than 10 parts per million. It has been found that many III-V semiconductor compounds that can be used as surface junction electroluminescence have high melting points and high vapor pressures at melting point temperatures. This disadvantage has been overcome to some extent by high-pressure crystal pulling, solution growth, and epitaxial growth. Both solution growth and epitaxial growth can be carried out at temperatures much lower than the melting point.

The technology of injecting amphoteric conductive carriers into p-n junctions assumes that both semiconductors can be doped as n-type and p-type. Many semiconductors, especially I-VI semiconductors, have only one conductivity type, namely n-type or p-type. When you try to create another type of carrier by doping, a vacancy compensation mechanism occurs that prevents this change. Fortunately, this phenomenon does not exist in III-V compounds, which is why people are committed to studying this type of compounds.

Bandgap As mentioned earlier, the energy of photon emission generated by a forward biased p-n junction has an upper limit equal to the bandgap of the semiconductor. In order to make a device that can produce the entire visible spectrum above 400 nanometers, the semiconductor bandgap is required to reach 3.1 electron volts. This is essential for the p-n junction to produce radiation. However, a new device has been developed that coats the surface of a small semiconductor chip with a layer of phosphor, whose function is to convert the typical infrared radiation of the semiconductor into visible light. This phosphor is of the anti-Stokes type.

Wide-bandgap semiconductors generally tend to require high melting points and high-temperature processes, which increases the difficulty of production.

Internal efficiency As mentioned earlier, the band structure of the semiconductor has a great influence on the efficiency of radiative recombination. Therefore, detailed measurements are required to verify the expected band structure.

Absorption and refractive index Although semiconductors are effective radiation generators, a considerable percentage of radiation is absorbed before it reaches the semiconductor surface. At the same time, since the refractive index of semiconductors is also relatively large, only a small part of the light energy is transmitted to the air interface, and the rest is lost in internal reflection. For example, the refractive index of gallium arsenide at its emission wavelength is 3.6, and the refractive index of gallium phosphide at 700 nanometers is 3.33 and 3.6 at 550 nanometers.

Mobility The current passing through the p-n junction should be as uniform as possible to ensure uniform brightness of the lamp. This means that the surface of the lamp should have sufficient conductivity, and the conductivity is related to the mobility of the carriers. High carrier mobility helps to obtain uniform emission.

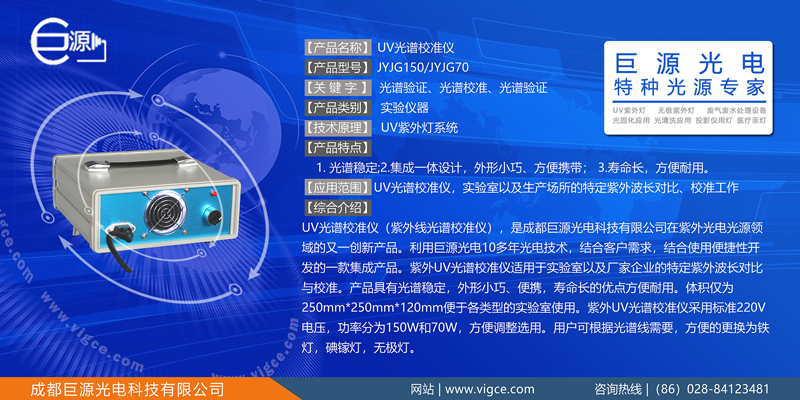

Contact: QianShuang

Phone: (86)028-84123481

Tel: (86)028-84123481

Email: vigce_com@126.com

Add: NO.66 GuiWangQiao West Road,Chengdu,Sichuan,P.R.China