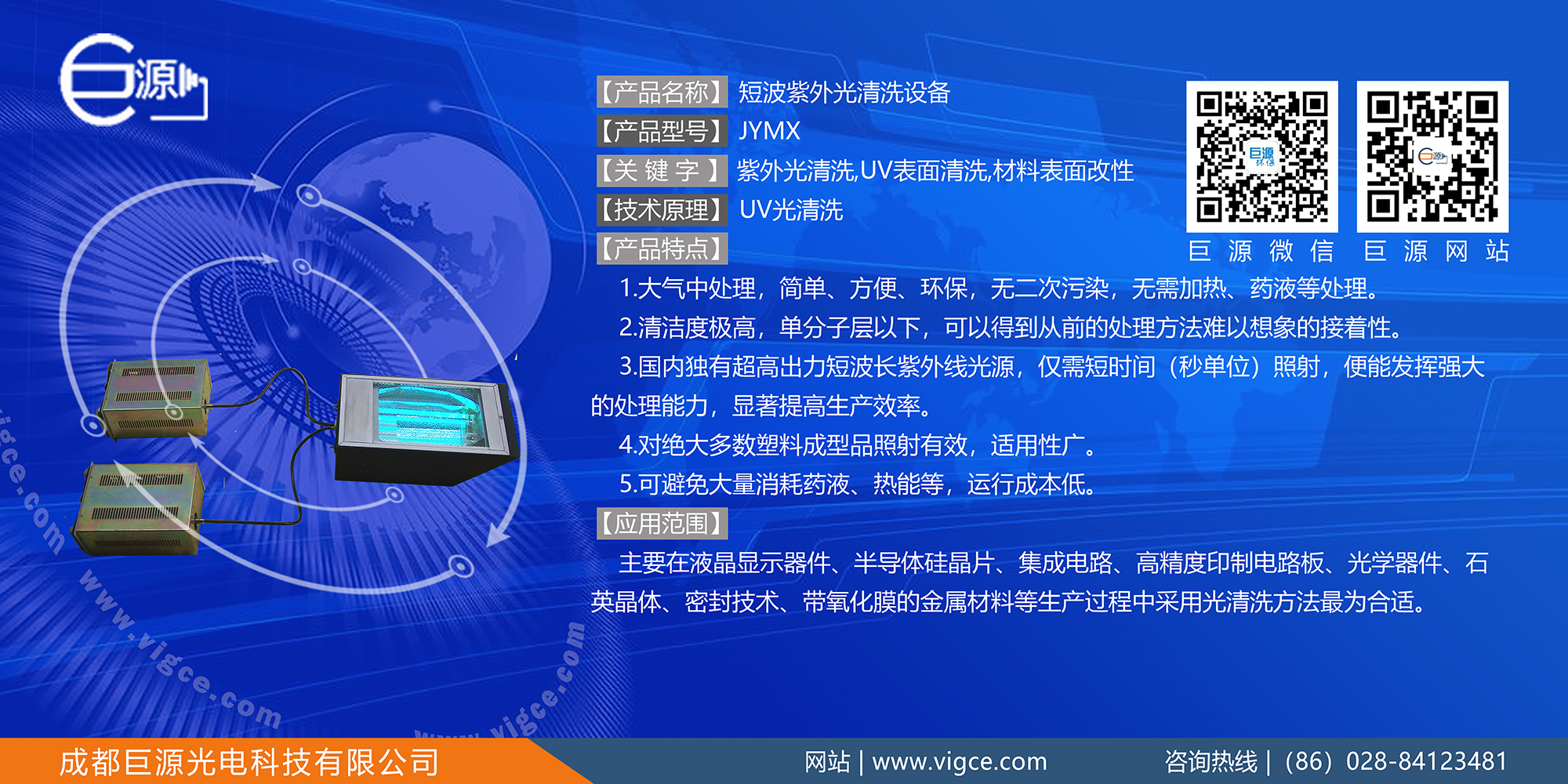

【产品名称】短波紫外光清洗设备

【产品型号】JYMX

【关 键 字】紫外光清洗设备,短波长紫外线,UV表面清洗,材料表面改性,UV氧化反应

【产品类别】UV光清洗器

【技术原理】使用短波长紫外线UV表面清洗、表面改性技术,用清洁高能紫外线光源,对材料进行处理后可得到极其清洁的表面和强力的表面接着性。

【产品特点】

1.大气中处理,简单、方便、环保,无二次污染,无需加热、药液等处理。

2.清洁度极高,单分子层以下,可以得到从前的处理方法难以想象的接着性。

3.国内独有超高出力短波长紫外线光源,仅需短时间(秒单位)照射,便能发挥强大的处理能力,显著提高生产效率。

4.对绝大多数塑料成型品照射有效,适用性广。

5.可避免大量消耗药液、热能等,运行成本低。

【应用范围】

主要在液晶显示器件、半导体硅晶片、集成电路、高精度印制电路板、光学器件、石英晶体、密封技术、带氧化膜的金属材料等生产过程中采用光清洗方法最为合适。

主要材料:ITO玻璃、光学玻璃、铬板、掩膜板、抛光石英晶体、硅晶片和 带有氧化膜的金属等进行精密清洗处理。

可以去除污垢:有机性污垢、人体皮脂、化妆品油脂、树脂添加剂及聚酰亚胺、石蜡、松香、润滑油、残余的光刻胶等。

此UV光源在LCD工艺中又具有UV改质(紫外光表面质变)的特点,目前在液晶显示器STN的生产过程中,主要是用在膜处理技术上,对于改善膜与膜之间的密接是非常有效的,如ITO膜与感光胶膜层,TOP涂层与PI涂层等等。另在研究部门又可用来UV改性塑料材料产品,用于纳米技术研究,产品经此UV光照射发生化学反应,使产品表面性质改变。

【综合介绍】

一般工业或高科技领域使用的一些材料具有非常高的性能,对环境也非常友好,但这些材料的接着性、印涂性等一般都非常差。本公司提供的短波长紫外线(UV)表面清洗、表面改性技术,用清洁的高能紫外线光源,对上述材料进行处理后可得到极其清洁的表面和强力的表面接着性。

改性的基本的反应就是UV引起的氧化反应。UV照射固体表面后,表面的污染物被氧化,而后被分解成CO2和H2O等易挥发性物质,最终挥发消失。并且表面形成有利表面接着的如OH,COO,CO,COOH等亲水性原子团,被改性的表面接着性得到飞跃性地提高。

UV光源技术的进步保证了UV/O3表面改性技术充分发挥其突出的优越性。UV/O3表面改性技术因能处理得到极高的清洁度与表面接着性,在固体表面处理中越来越得到广泛的应用。

【使用说明】

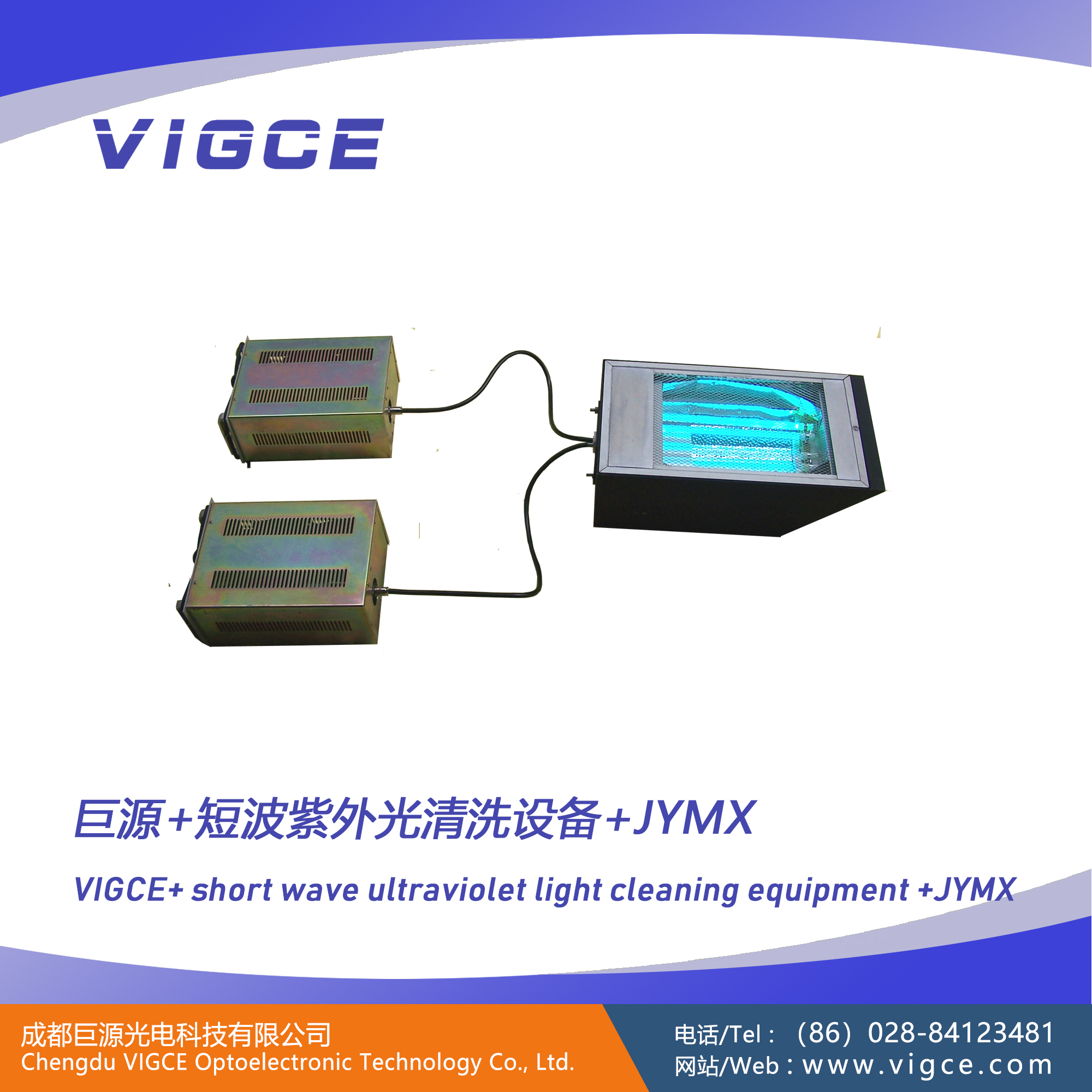

【产品照片】

【视频资料】

【同系产品】

【规格参数】

[product name] short wave ultraviolet light cleaning equipment

[product model] JYMX

Ultraviolet light cleaning equipment, short wave long ultraviolet, UV surface cleaning, material surface modification, UV oxidation reaction

[product category] UV light cleaner

[technology principle] using short wavelength ultraviolet UV surface cleaning and surface modification technology, using clean high-energy ultraviolet light source to process materials, we can get extremely clean surface and strong surface continuity.

[product characteristics]

1. treatment in the atmosphere, simple, convenient, environmental protection, no two pollution, no heating, liquid and other treatment.

2. the cleanliness is very high and the single molecular layer is below, and the unimaginable continuity of the previous treatment can be obtained.

3., China's unique ultra high output, short wavelength ultraviolet light source, only needs a short time (seconds unit) to irradiate, can play a powerful processing capacity, significantly improve production efficiency.

4. is effective for most plastic molding products, and it is widely applicable.

5. can avoid a large amount of consumption of liquid, heat and so on, low operating cost.

[application range]

Mainly in liquid crystal display devices, semiconductor silicon wafers, integrated circuits, high-precision printed circuit boards, optical devices, quartz crystal, sealing technology, metal materials with oxide film and other production processes, the most suitable method is optical cleaning.

The main materials are ITO glass, optical glass, chromium plate, mask, polished quartz crystal, silicon wafer and metal with oxide film for precise cleaning.

It can remove dirt: organic dirt, human sebum, cosmetic oil, resin additives and polyimide, paraffin, rosin, lubricating oil, residual photoresist and so on.

The UV light source has UV modification in the LCD process (UV surface characteristics, the qualitative change) in the production process of liquid crystal display STN, is mainly used in film processing technology, is very effective for improving membrane and membrane contact, such as ITO film and photosensitive adhesive coating, TOP coating and PI coating and so on. In addition, the research department can also be used for UV modified plastic products, for nano technology research. Products are irradiated by UV light to produce chemical reactions, so that the surface properties of products are changed.

[comprehensive introduction]

Some materials used in general industrial or hi-tech fields have very high performance and are also very friendly to the environment, but these materials are usually very poor. The short wavelength ultraviolet (UV) surface cleaning and surface modification technology provided by our company is processed with clean high-energy ultraviolet light source. After that, we can get extremely clean surface and strong surface continuity.

The basic reaction of modification is the oxidation reaction caused by UV. After UV is irradiated on the surface of the solid, the pollutants on the surface are oxidized and then decomposed into volatile substances such as CO2 and H2O, which eventually evaporate. And the surface formed a favorable surface followed by a hydrophilic group such as OH, COO, CO, COOH and other hydrophilic groups, and the modified surface continuity was greatly improved.

The progress of the UV light source technology ensures the UV/O3 surface modification technology to give full play to its outstanding superiority. UV/O3 surface modification technology is becoming more and more widely used in solid surface treatment because of its high cleanliness and surface continuity.

[instructions]

[product photo]

[video data]

[homologous products]

[specification parameter]

.

联系人:销售部

手机:(86)028-84123481

电话:(86)028-84123481

邮箱:vigce_com@126.com

地址: 四川省成都市锦江区桂王桥西街66号